Fields of

APPLICATION

Application areas

Pump solutions suitable for several areas.

The application areas of our pumps are divers and extensive especially in the industrial sector.

Mining

Contacts Mining

Contact our Mining Team through email or the contact form below.

mining@duechting.com

Contact our Mining Team directly though this contact form:

When mining coal and ore underground, the pit water which accumulates has to be pumped away to prevent it from flowing through the working area. Normally this is done by pumping the pit water to the surface. Right from the start DÜCHTING PUMPEN created a solution for removing the water in the mine using heavy-duty centrifugal high-pressure pumps.

The high-pressure pumps of the HPXU series, of conventional construction with a high voltage motor, are set up in underground chambers excavated for this purpose. The collected pit water is usually fed to the high-pressure pumps via water collection points either by free flow or by means of feeder pumps. Pit water is not completely free of solid particles and chemical compound. For this reason, DÜCHTING PUMPEN typically utilizes 4-pole speet as a standard with high-grade austenitic stainless steel as the material. If the pit water is particularly pure, higher speeds are economically possible with two-pole motors.

Thanks to the high performance of the HPXU pumps, the expense of pumping from level to level is avoided and the possibility of automating this type of pumping station becomes economical. In comparison to submersible pumps, high-pressure pumps of conventional build have proven their worth due to their robustness and long life.

High-pressure pumps of the HPXU series in conjunction with the DÜCHTING PUMPEN WRX series can also be used for hydraulic extraction. If there is suitable pit water available and the environment is right, this type of extraction can be more economical for suitable seam thickness.

High-pressure pumps of the HPXU and HPXL range are also used in mines for cooling systems that utilize large heat exchangers. For decades now, our medium-size HPXU10 series has been the most frequently bought pump for secondary water retention.

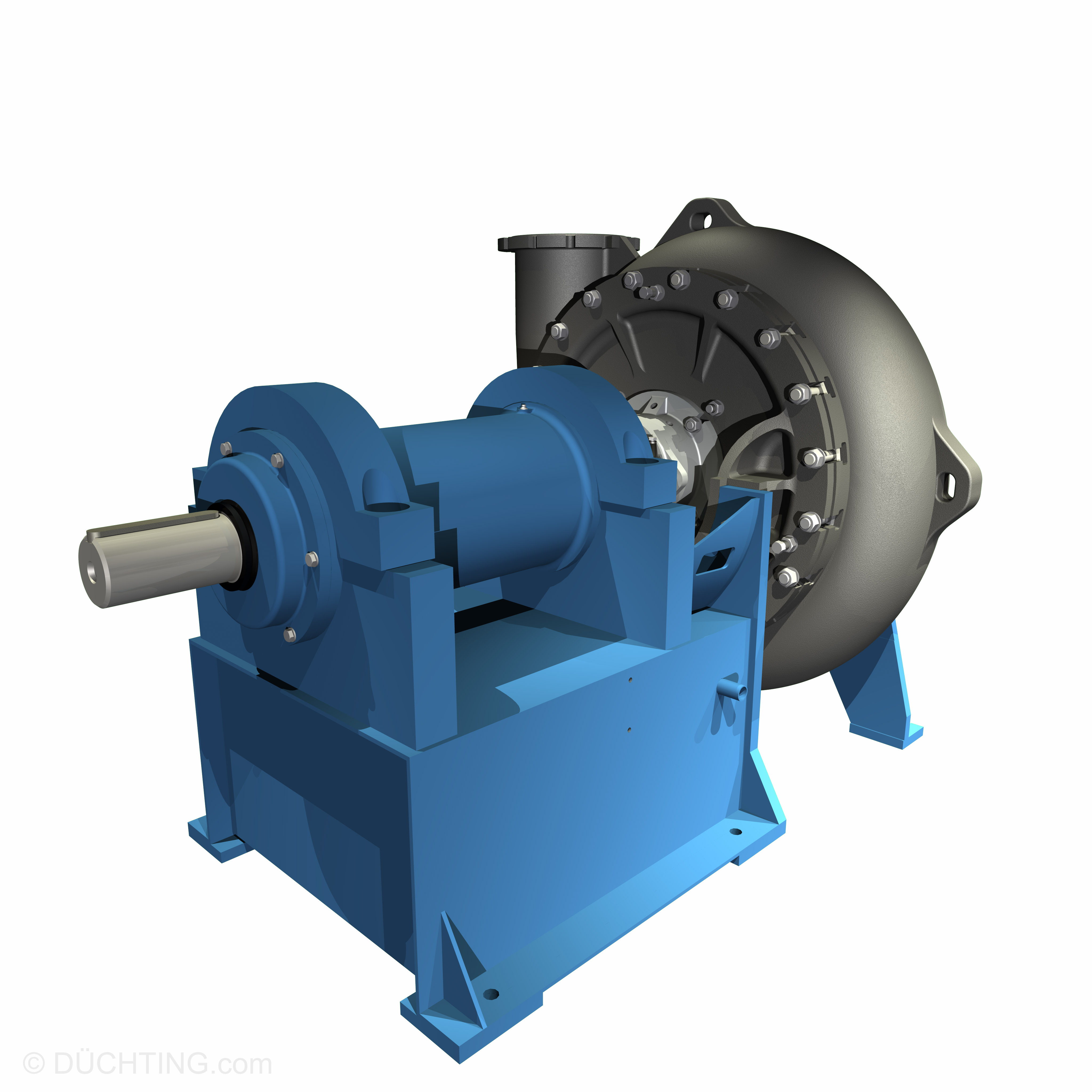

As far as the exploitation of coal and ore at surface level is concerned, DÜCHTING PUMPEN can offer a very robust and – as a result of its high operating ratio – also a very efficient solution with its WRX series. Due to their construction, all known high carbon steels can be built into the WRX pumps.

The wear plates are clamped in. The modular construction of the WRX range allows for an optimal selection of sizes, tailor made for the specific application. The back pull out design of the WRX series allows for easy inspection of wear components requiring minimum effort.

HPXU & HPXM

DN 32 (1 1/4") to DN 400 (16")

max. Pressure 160 bar

max. Flow 15000 gpm

Type WRX

DN 200 (8") to DN 400 (16")

max. Pressure 10 bar (150 PSI)

max. Flow 22000 gpm

Type WR

DN 32 (1 1/4") to DN 800 (32")

max. Pressure 16 bar

max. Flow 80000 gpm

Type HPXL

DN 32 (1 1/4") to DN 300 (12")

max. Pressure 40 bar

max. Flow 11000 gpm

Application areas

The main fields we serve.

Contact

Get In Touch

Please use our contact form for a quick contact with us. We will try to get back to you as soon as possible.