Product

PORTFOLIO

Our selection of centrifugal pumps in single-stage or multi-stage design.

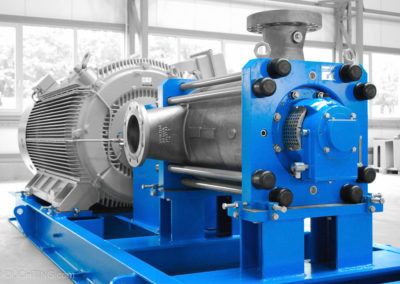

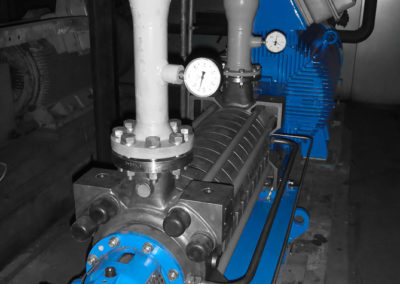

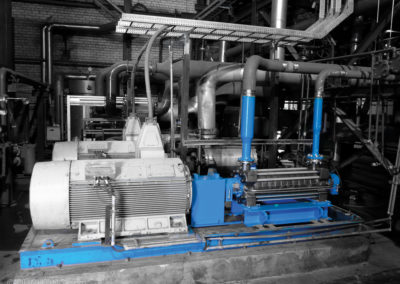

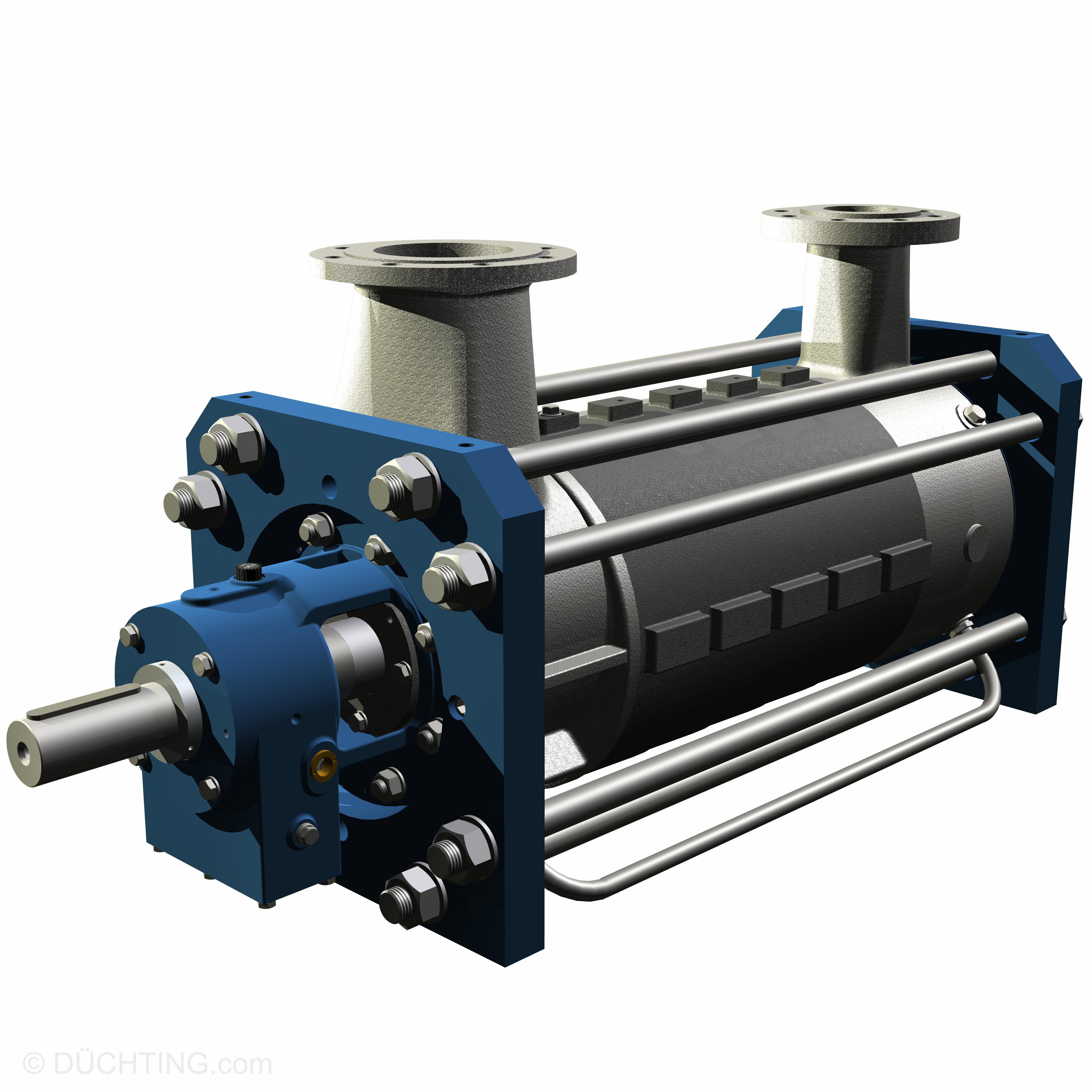

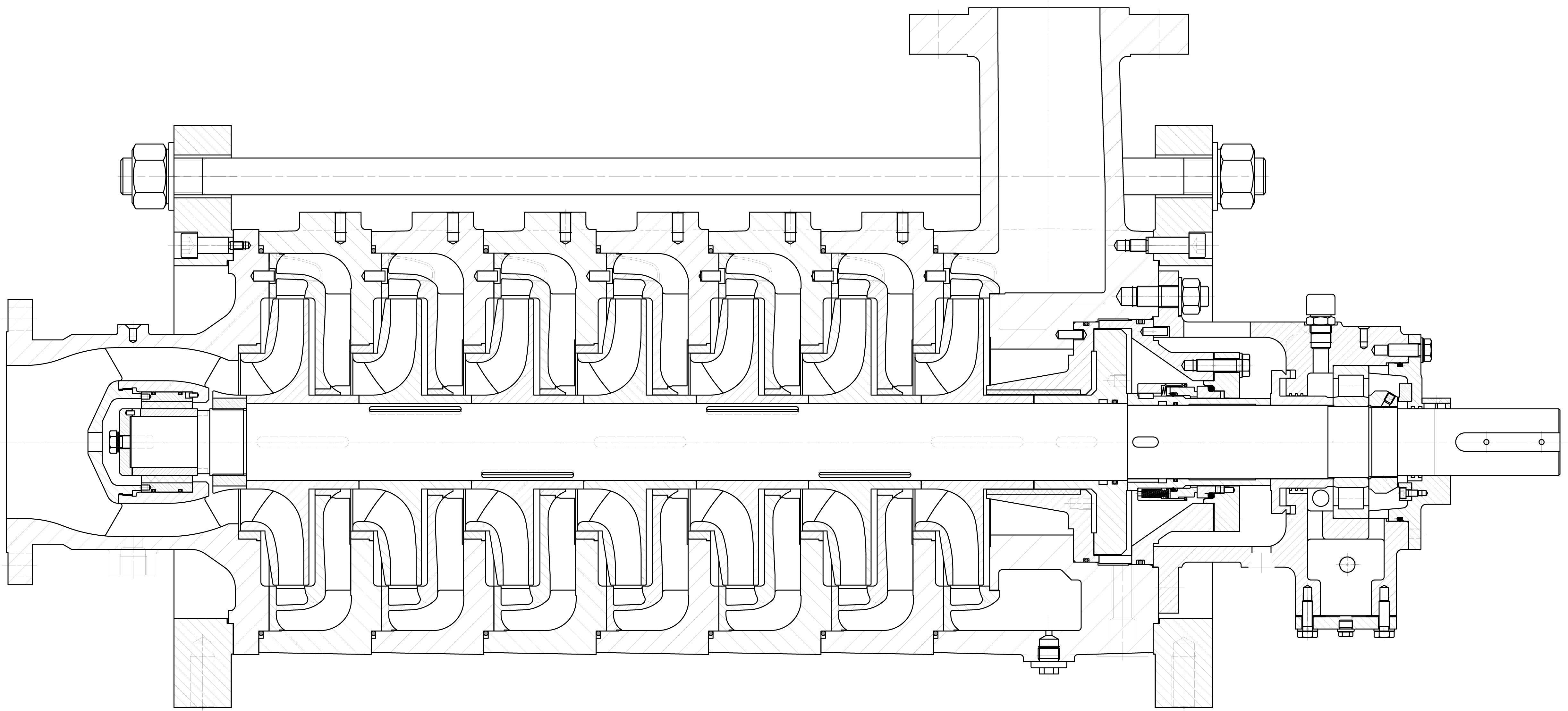

TyPE hPH

Multi stage centrifugal pumps in ring-section design.

- Pump inlet: axial or radial with flanges positioned at 90° increments

- Discharge flange: radial positioned at 90° increments

- Replacable rings in composite material to maintain best efficiency and reliability

- Shaft sealing by stuffing box or mechanical seal

- Axial thrust compensation by balancing discs, balancing drum or combination of both

- Easy replacement of all wearing parts

- Tailormade solutions available:

- Pump dimensions can be adapted to customer requirements

- Impellers are fixed by fitting key (e.g. backflushing) possible

- Impeller wear rings available

- Pump with one or two connective shaft ends

- Impellers and diffusers are cast by using ceramic moulds to get smooth surfaces for outstanding hydraulic performance

Technical Data

| Pump Size: | 3″ to 12″ |

| max. Pressure: | 1450 PSI |

| max. Flow: | 15400 gpm |

| Total head: | up to 3600 ft |

| Rotating speed: | to 3600 rpm |

Fields of Application

Handling of clean or slightly polluted, chemically neutral or aggressive liquids.

- Pressure boosting systems in industrial process

- Water supply, and water treatment

- Seawater desalination

- Condensate production

- Boiler feed systems

- Hot water applications

- Petrochemical applications

- Water Injection

Materials

Carefully selected depending on the application and adapted to the respective conditions.

DÜCHTING PUMPEN offers improved corrosion resistant materials like SUPER DUPLEX stainless steel with Pitting Resistance Equivalent numbers above 40.

Standards & Approvals

Manufactured according to ISO, DIN and ASME (API 610 / ISO 13709) possible

Contact

Get In Touch

Please use our contact form for a quick contact with us. We will try to get back to you as soon as possible.