Fields of

APPLICATION

Application areas

Pump solutions suitable for several areas.

The application areas of our pumps are divers and extensive especially in the industrial sector.

Seawater Desalination

Contact Seawater Desalination

Contact our Seawater Team through email or the contact form below.

seawater@duechting.com

Contact our Seawater Team directly though this contact form:

Two thirds of the surface of our planet is covered with water, yet providing the population of the world with high-quality drinking water is becoming increasingly difficult not only in arid regions, but also in the conurbations of industrial countries. Even today, existing resources cannot be fully exploited, for instance as a result of the contamination of ground water with nitrates and the lowering of the water table.

So what would be more obvious than using the large quantities of seawater available for the provision of high-quality drinking water?

Along with the thermal process, reverse osmosis – a process that is based on membrane technology – is becoming increasingly popular for the industrial desalination of seawater. However, the complexity of these kinds of desalination systems requires plant components that meet high technical standards.

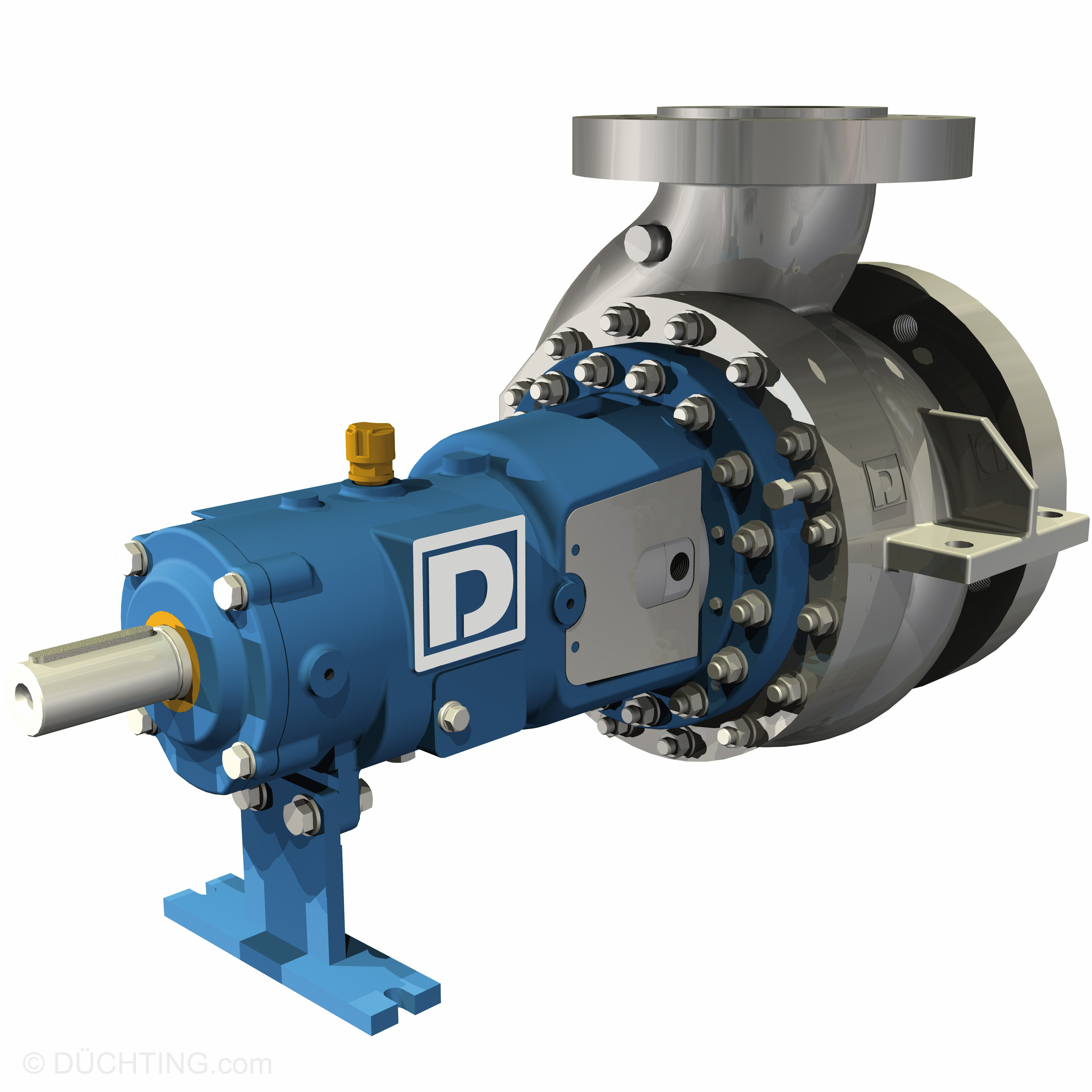

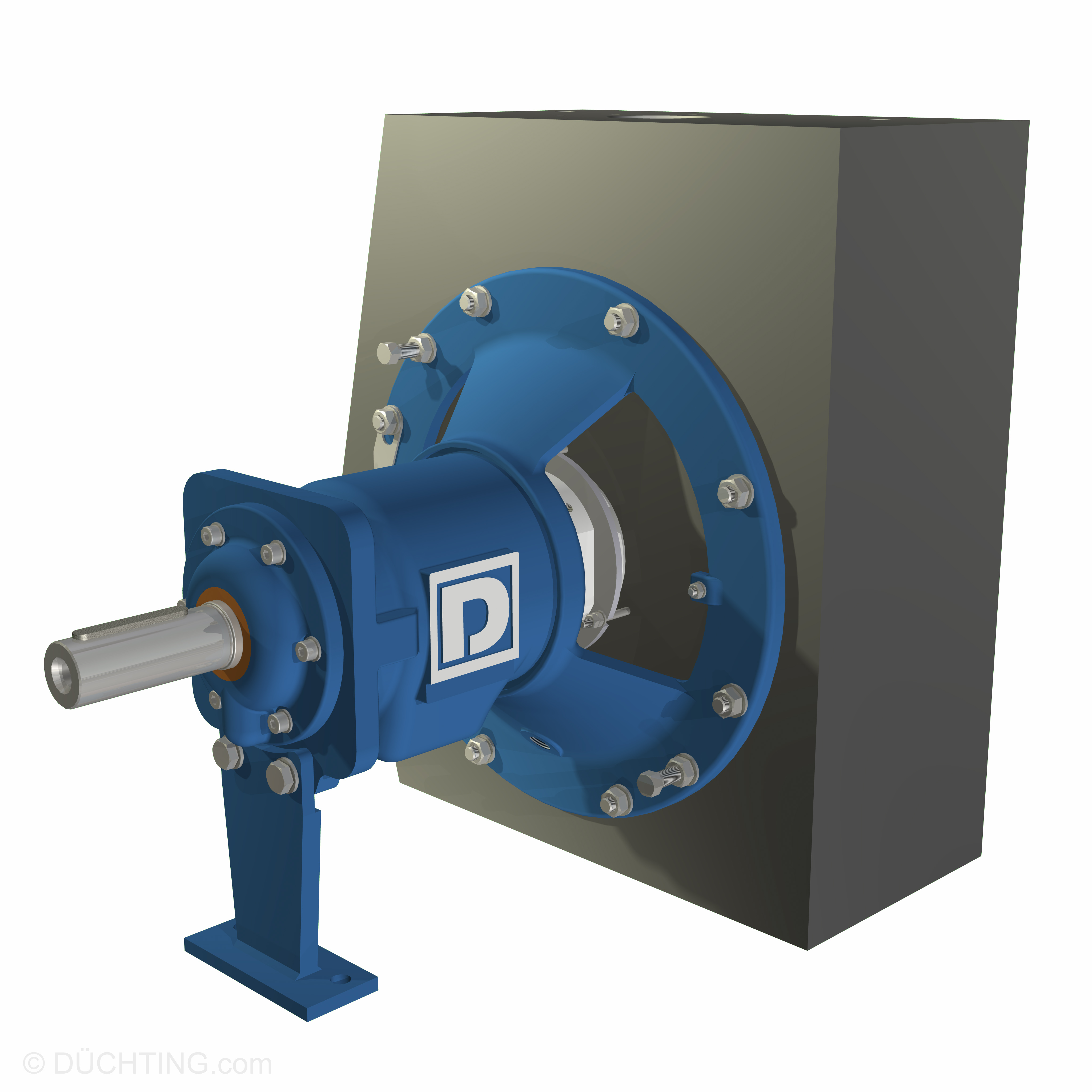

High-pressure pumps are feeding the membranes with seawater form the heart of reverse osmosis plants. With the HPH and HPXU series, DÜCHTING PUMPEN offers multi-stage high-pressure centrifugal pumps that are particularly suitable for the desalination of seawater. The choice of the right pump and of the right stainless-steel materials suitable for seawater has a crucial impact on the plant availability and, of course, also on its economic viability. Hydraulics that have been especially designed for this application guarantee optimal efficiencies at the pumps’ operating point.

It is important to note that the energy requirements of the reverse osmosis process can be reduced considerably, since the high pressure energy of the flow that is left at the end of the desalination process can be used for energy recovery: By means of a Pelton turbine, this pressure energy is led back into the system by coupling the turbine shaft directly to the pump shaft. This helps to reduce the power of the drive that needs to be installed for the high-pressure pump. As a result, up to 45 % of the drive energy required can be led back into the system. For other ERT systems, the development is still open.

DÜCHTING PUMPEN offers tailor-made plant solutions and complete pump trains that consist of a high-pressure pump, a drive motor and a Pelton turbine.

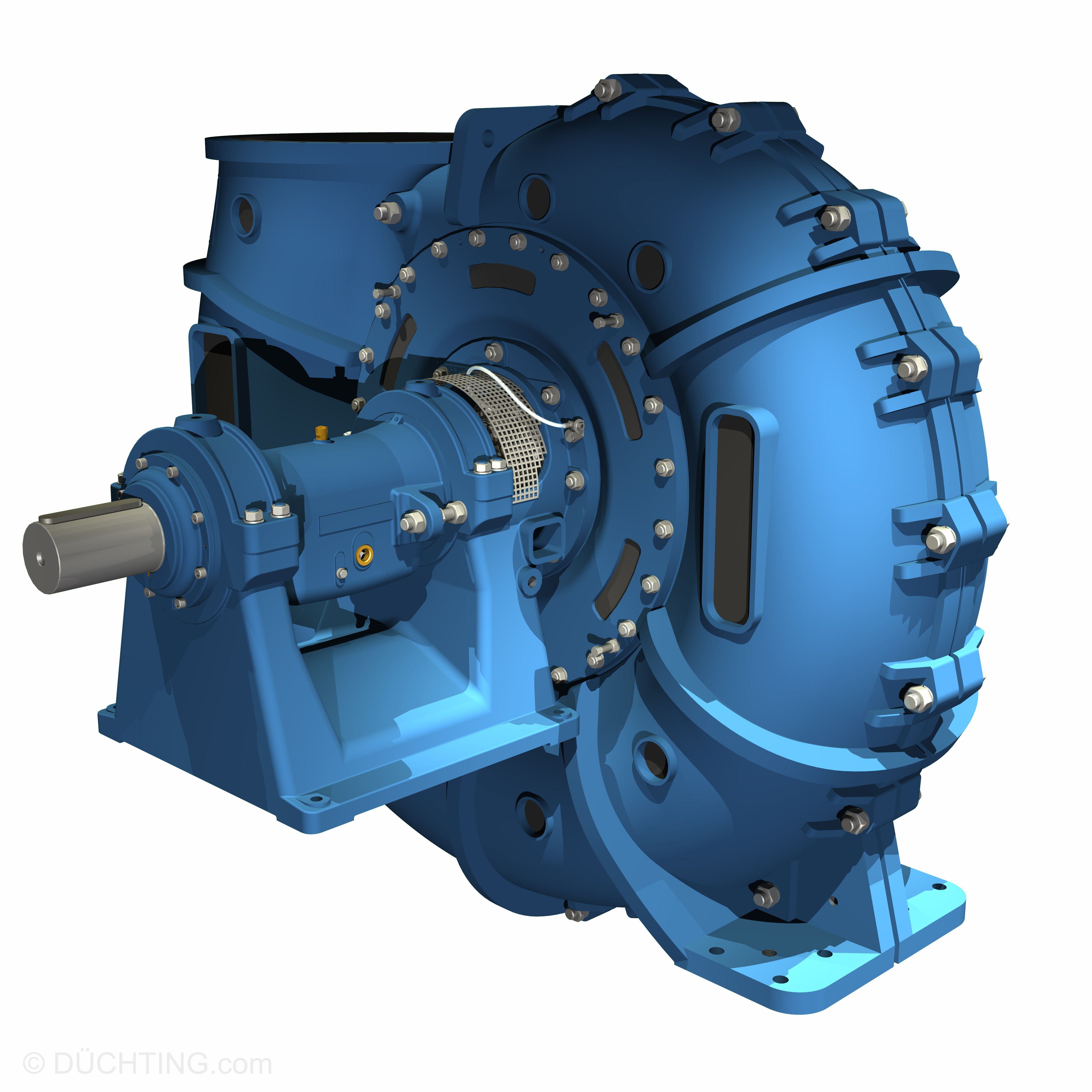

Type IP

DN 50 (2 1/2") to DN 450 (18")

max. Pressure 100 bar

max. Flow 18500 gpm

Type MC

DN 32 (1 1/4") to DN 300 (12")

max. Pressure 10 bar

max. Flow 6600 gpm

Type MCC

DN 400 (16") to DN 1000 (40")

max. Pressure 6 bar

max. Flow 88000 gpm

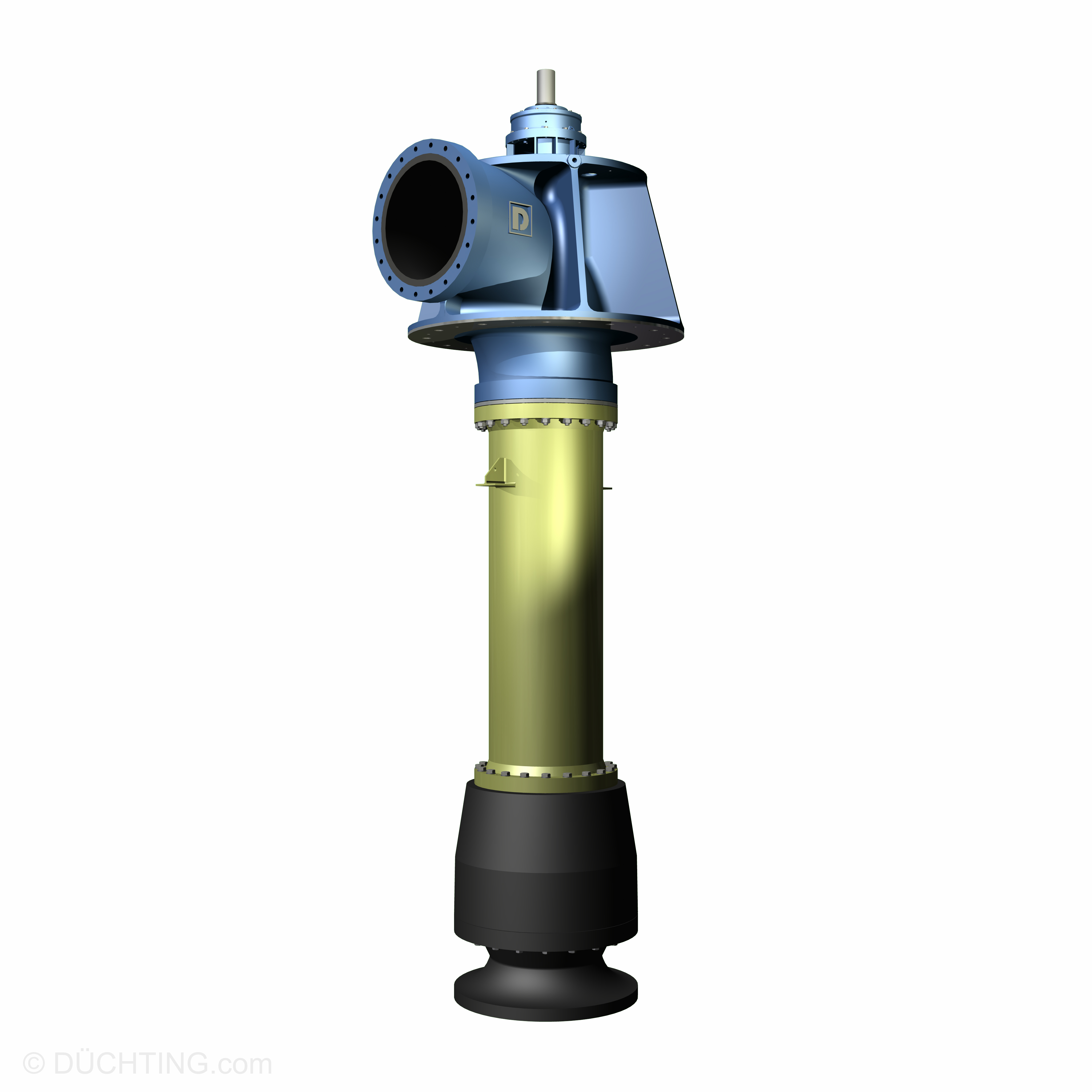

Type MCV

DN 150 (6") to DN 1000 (40")

max. Pressure 8 bar

max. Flow 55000 gpm

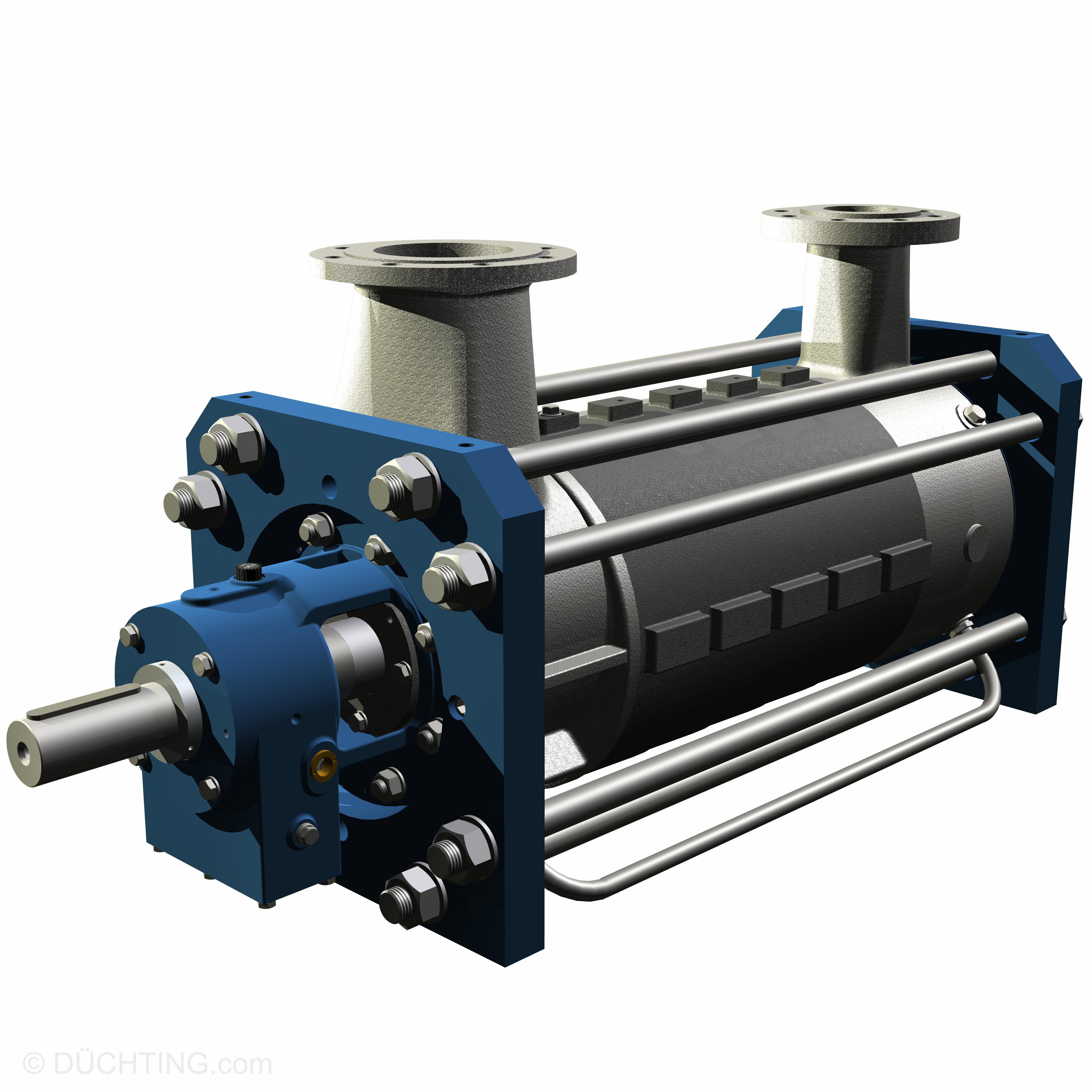

Type HPH

DN 80 (3") to DN 300 (12")

max. Pressure 100 bar

max. Flow 15400 gpm

Application areas

The main fields we serve.

Contact

Get In Touch

Please use our contact form for a quick contact with us. We will try to get back to you as soon as possible.

Subscribe to our Mailinglist!

Be a part of the DÜCHTING mailinglist and receive regular news, updates and stories about our products, partners and employees.