Product

PORTFOLIO

Our selection of centrifugal pumps in single-stage or multi-stage design.

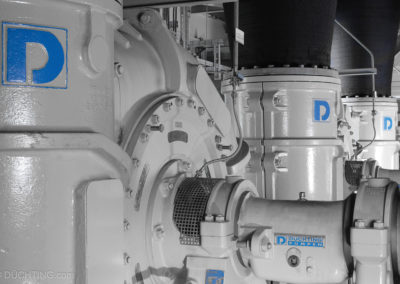

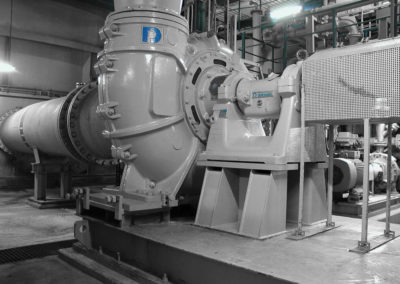

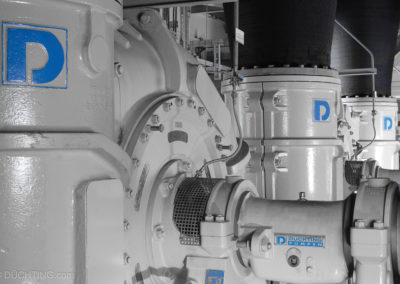

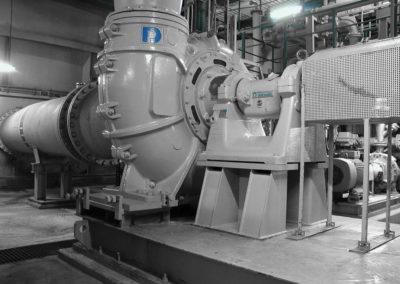

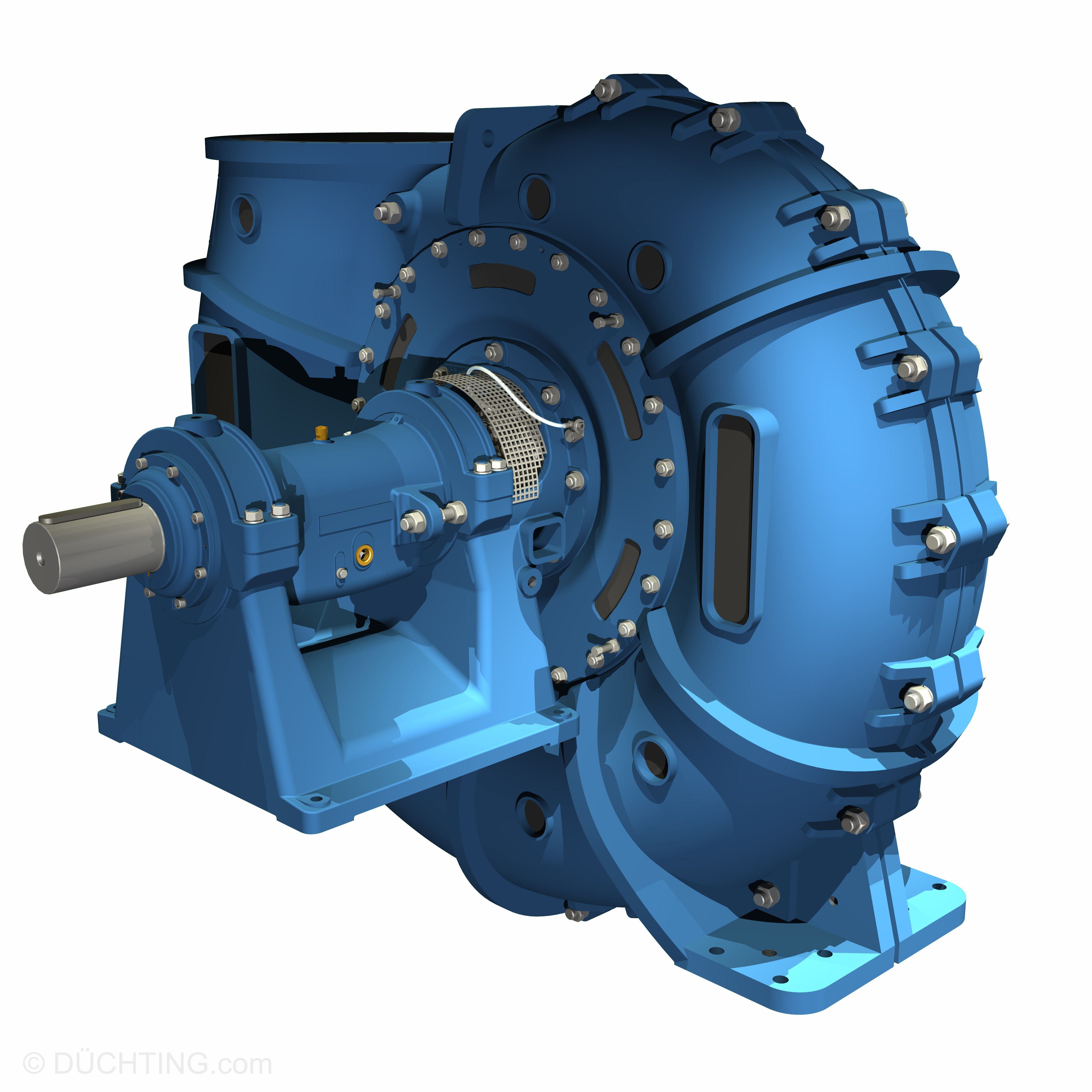

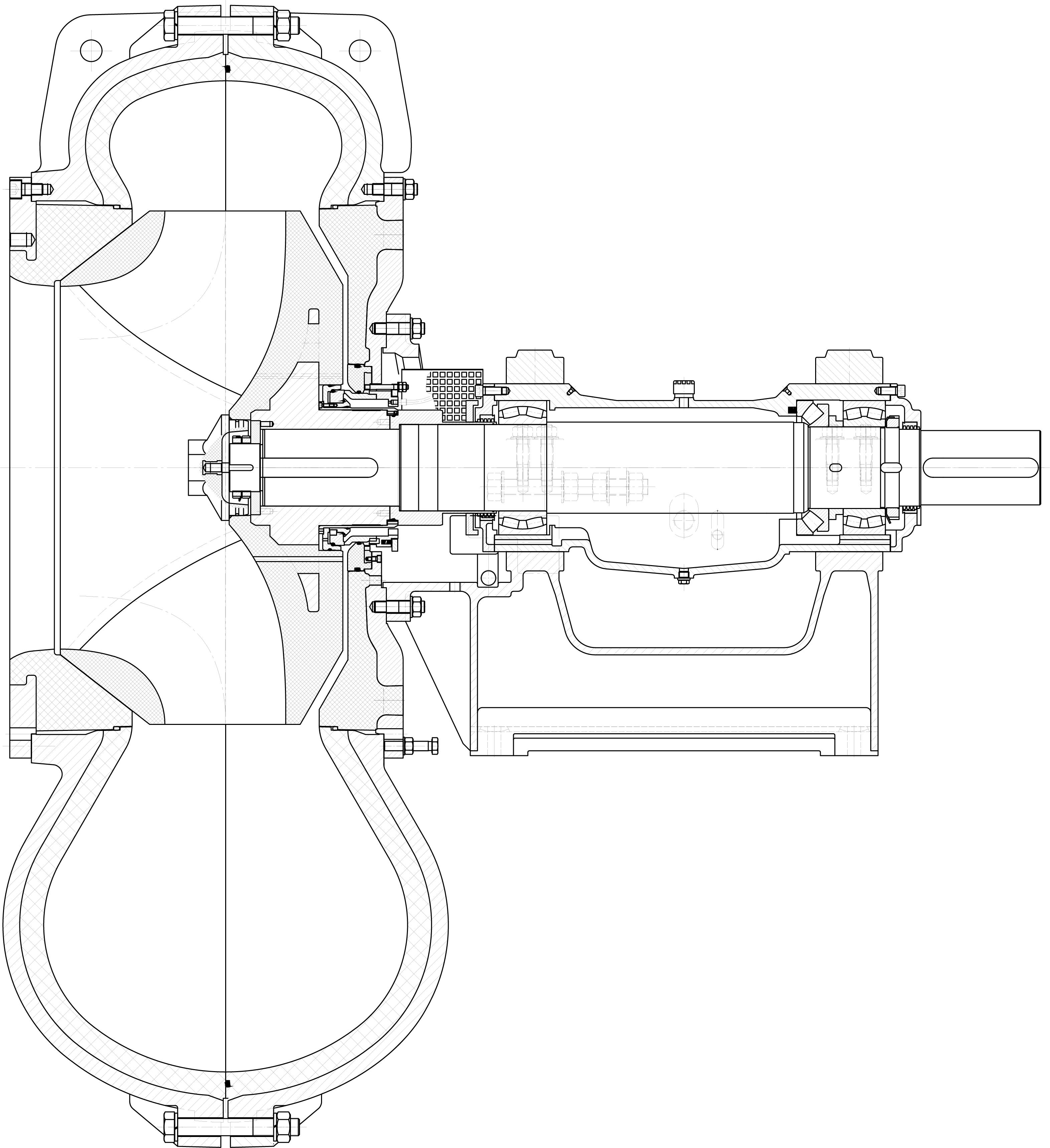

TyPE MCC

Horizontal single-stage centrifugal pump in back pullout design.

- Pumping of abrasive and corrosive liquids

- All components which are in contact with the liquid are made of SICcast

- Suction flange: Axial

- Discharge flange: Top (Tangential)

- Closed impeller with three-dimensionally curved vanes

- Impeller is key driven; reverse rotation (e.g. back-flushing) is possible

- Re-adjustable inclined gap between impeller and wear plate to optimize the efficiency and differential pressure after longer operation

- Single acting, metal free cartridge mechanical seal DÜTEC-C with springs located outside of the liquid

- Durable, oil-lubricated roller bearings

- Back pullout design (the complete rotating equipment can be disassembled while the casing remains on its position)

- In many applications the wear life of SICcast greetly exceeds conventional materials

- The patented design allows the production of extremely large pumps at low costs

- Currently, the most advanced and most durable technology for FGD absorber recirculation pumps

Technical Data

| Pump Size: | 16″ to 40″ |

| max. Pressure: | 87 PSI |

| max. Flow: | 88000 gpm |

| Total head: | up to 130 ft |

| Rotating speed: | to 1200 rpm |

Fields of Application

Pumping abrasive and / or corrosive media.

- Flue gas desulfurization

- Incinerators

- Water treatment

- Seawater desalination

Materials

| Spiral casing: | SICcast® EN-GJS-400-15 (GGG40) |

| Impeller: | SICcast® |

| Wear plate: | SICcast® |

| Shaft: | 1.0503 (C45) |

| Shaft sleeve: | 1.4301 (1.4462) |

| Mechanical seal: | Silicon carbide (SiC) |

Contact

Get In Touch

Please use our contact form for a quick contact with us. We will try to get back to you as soon as possible.