70 / 100

Product

PORTFOLIO

Our selection of centrifugal pumps in single-stage or multi-stage design.

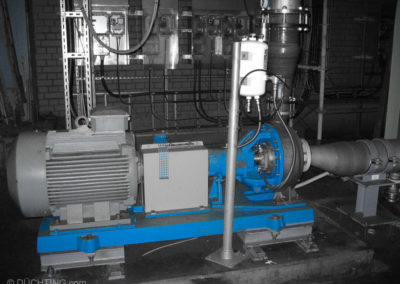

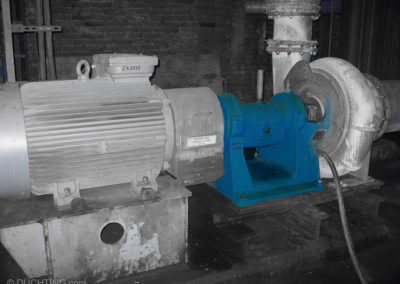

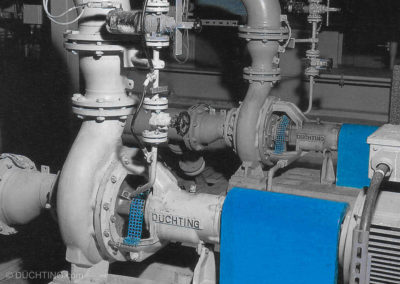

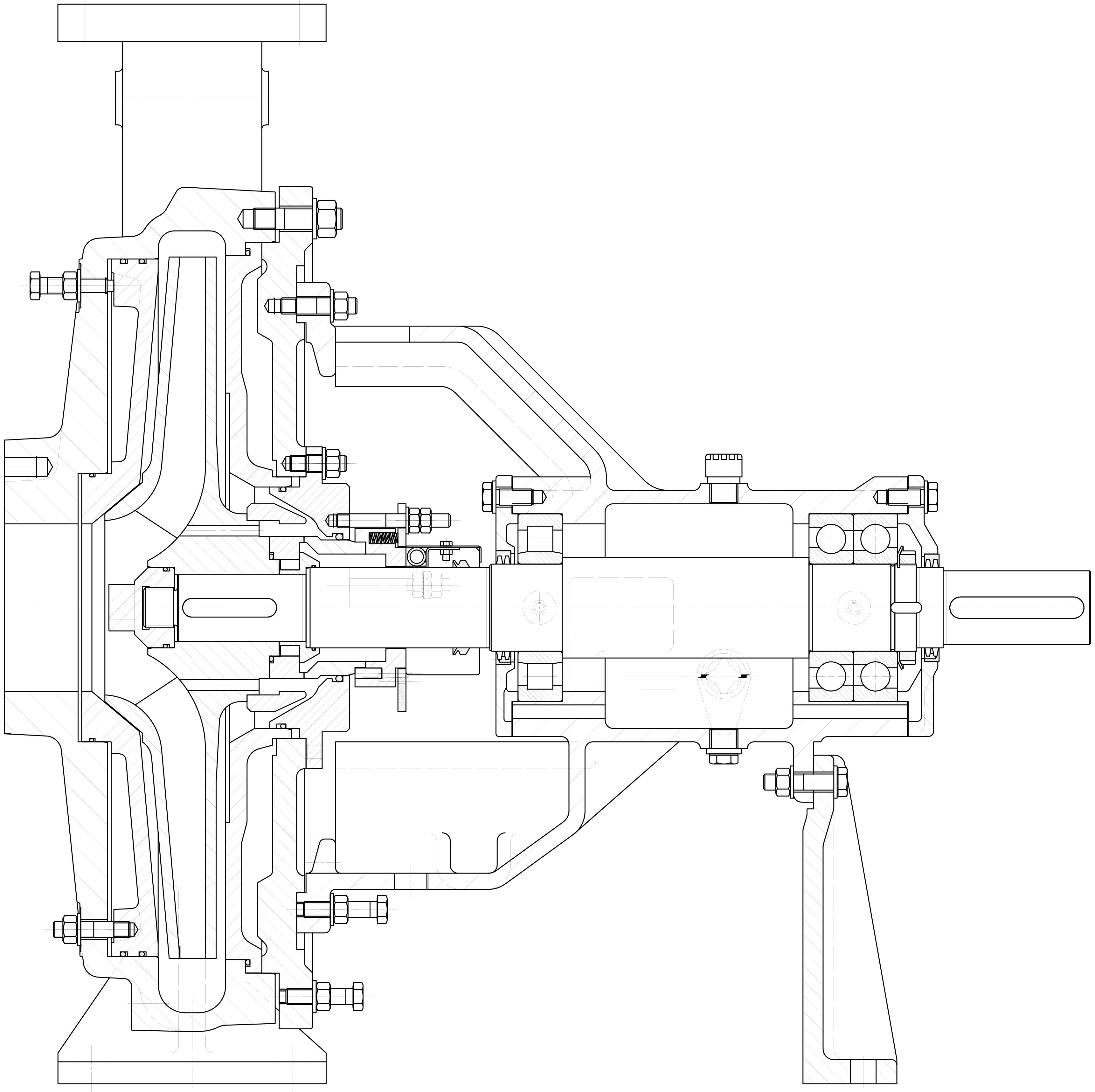

TyPE wr

Horizontal single-stage centrifugal pump in back pullout design.

- Pumping of abrasive and corrosive liquids

- Suction flange: axial

- Discharge flange: Top (DN 32 to DN 250 vertical, from DN 300 tangential)

- Closed and open impeller available

- Impeller is keyed to the shaft; reverse rotation (e.g. back-flushing) is possible

- Re-adjustable inclined gap between the impeller and volute casing to optimize the efficiency and differential pressure after prolonged operation

- Shaft sealing by means of DÜTEC single mechanical seal with external springs (gland packing and other mechanical seals available)

- Durable, oil-lubricated roller bearings

- Back pullout design (the complete rotating assembly can be removed while the casing remains on its position)

- Optimized design ensures easy maintenance and long service life even under difficult conditions

- Direct or belt driven

- Different arrangements available

Technical Data

| Pump Size: | 1 1/4″ to 32″ |

| max. Pressure: | 230 PSI |

| max. Flow: | 52800 gpm |

| Total head: | up to 395 ft |

| Rotating speed: | to 3600 rpm |

Fields of Application

Pumping of abrasive and corrosive media.

- Flue gas desulfurization (lime / gypsum slurries)

- Aluminum industry (aluminate)

- Cleaning equipment for heat exchangers

- Construction industry (cement-water mixture)

- Potash industry (caustic potash solution, mixed salts/brine)

- incinerators

- Mineral processing and refining

Materials

Available in almost any metal from cast iron to SUPER DUPLEX stainless steel.

The materials are carefully selected depending on the application, the pumped medium and the combinations of materials adapted to the respective conditions of use.

Contact

Get In Touch

Please use our contact form for a quick contact with us. We will try to get back to you as soon as possible.