Product

PORTFOLIO

Our selection of centrifugal pumps in single-stage or multi-stage design.

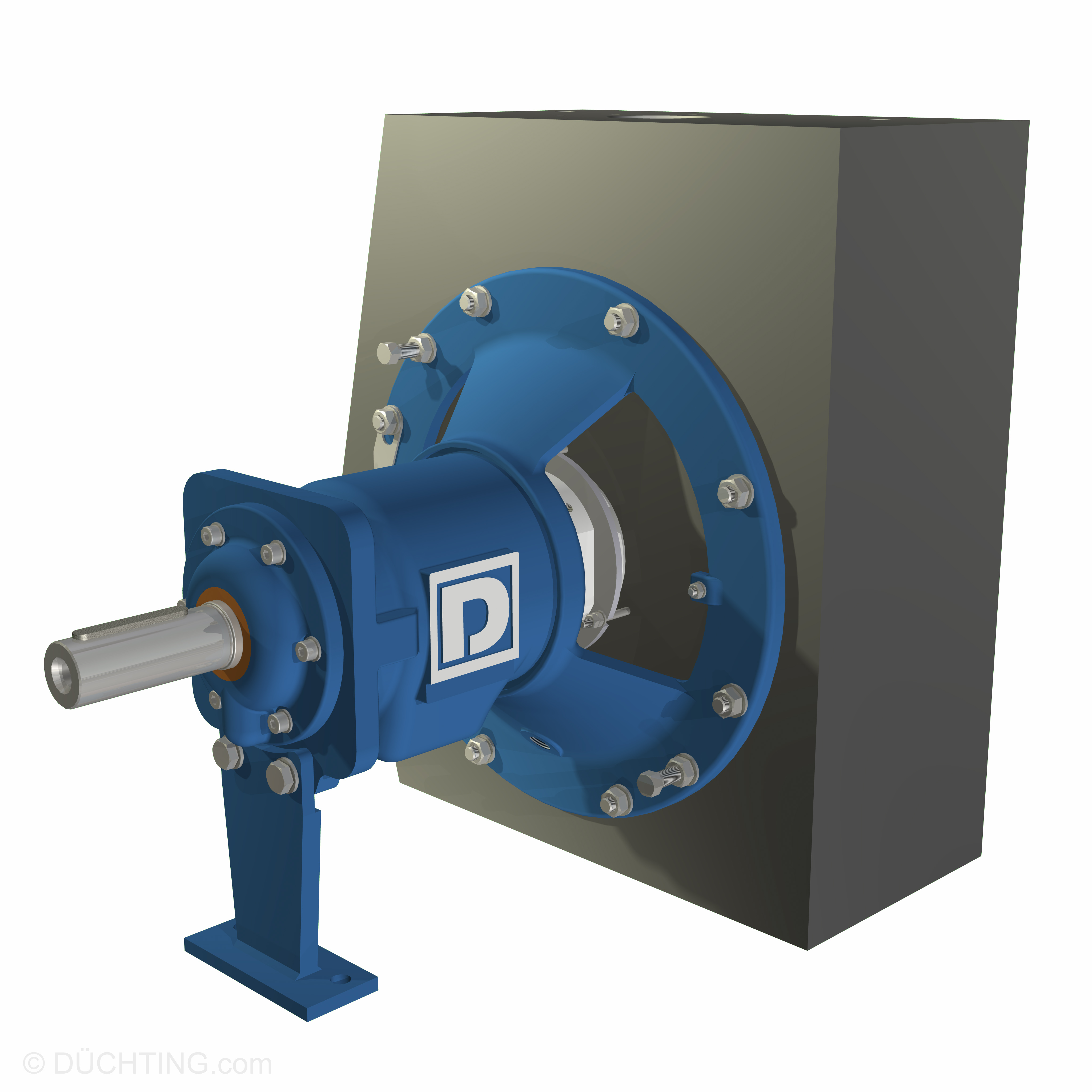

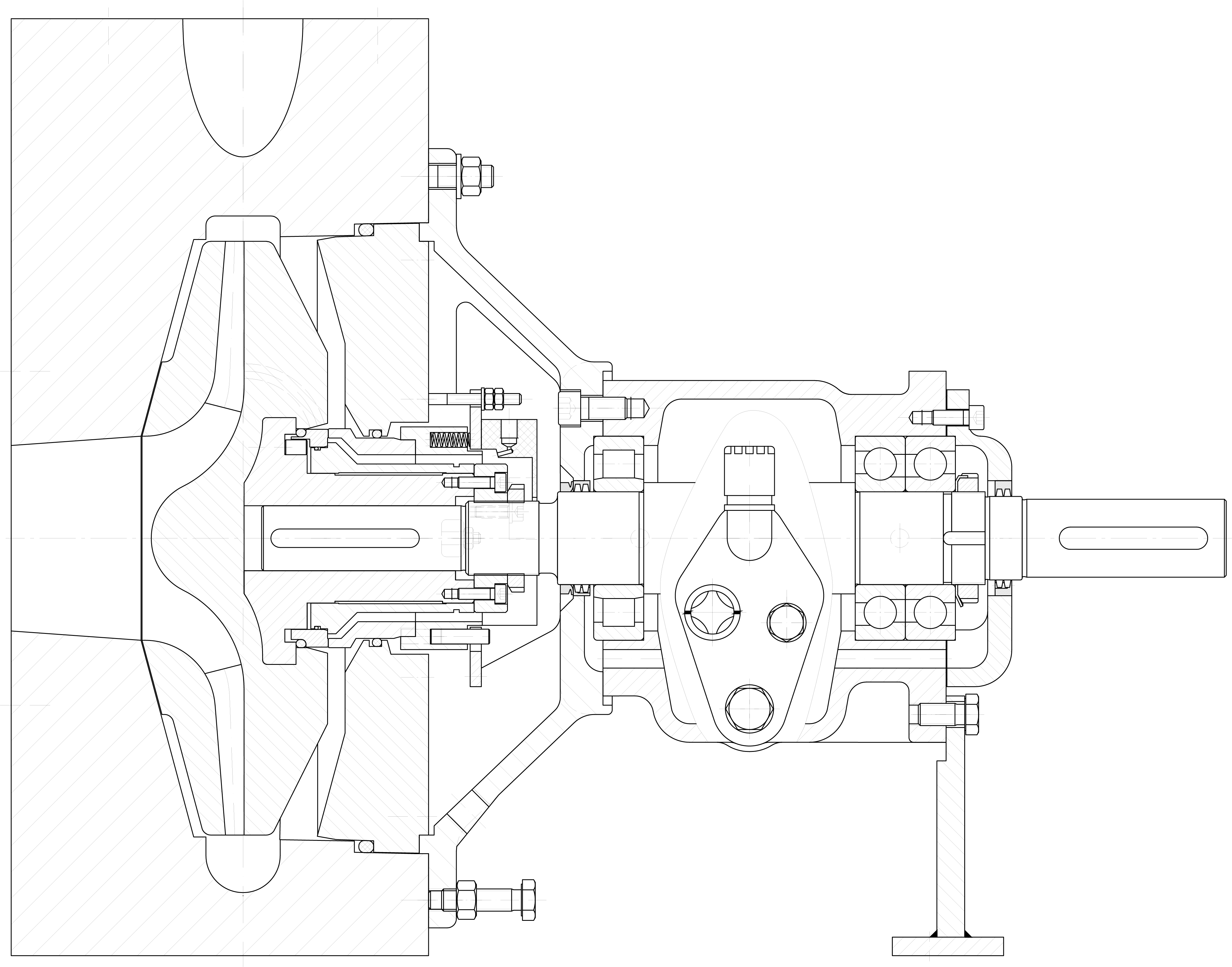

TyPE MC

Horizontal single-stage centrifugal pump in back pullout design.

- Pumping of abrasive and corrosive liquids

- All components which are in contact with the liquid are made of SICcast

- Suction flange: Axial

- Discharge flange: Top (Vertical)

- Closed impeller with three-dimensionally curved vanes

- Impeller is key driven; reverse rotation (e.g. back-flushing) is possible

- Re-adjustable inclined gap between impeller and volute casing to optimize the efficiency and differential pressure after longer operation

- Single acting, metal free mechanical seal DÜTEC with springs located outside of the liquid (other seal types available)

- Oil-lubricated antifriction bearings

- Back pullout design (the complete rotating assembly can be removed while the casing remains on its position)

- In many applications the wear life of SICcast greatly exceeds convential materials

- Available with heavy-duty bearing units for extreme applications

- Optimized design ensures easy maintenance and long service life even under difficult conditions

Technical Data

| Pump Size: | 1 1/4″ to 12″ |

| max. Pressure: | 150 PSI |

| max. Flow: | 6600 gpm |

| Total head: | up to 300 ft |

| Rotating speed: | to 3600 rpm |

Fields of Application

Pumping of abrasive and corrosive media

- Flue gas desulfurization

- Incinerators

- Pigment industry

- Chem. industry

- Water treatment

- Seawater desalination plants

- Fertilizer industry / Potash industry

Materials

Spiral casing: SICcast

Impeller: SICcast

Shaft: 1.4462

Mechanical seal: Silicon carbide (SiC)

Contact

Get In Touch

Please use our contact form for a quick contact with us. We will try to get back to you as soon as possible.